What is E1450

E1450, also known as distarch phosphate, is a type of modified starch created by treating natural starch—often from corn, potato, or tapioca—with phosphate salts. This process changes its structure, enhancing its stability and performance in food applications. Unlike native starch, E1450 can better handle heat, acid, freezing, and mechanical stress, making it a favourite in both industrial and everyday food production.

Functional properties of E1450

E1450 offers several technological advantages in food manufacturing:

- Thickening agent – Improves product viscosity without altering flavour

- Stabiliser – Maintains uniform consistency in sauces, soups, and dressings

- Texture improvement – Enhances mouthfeel in dairy, bakery, and processed foods

- Freeze-thaw stability – Prevents water separation in frozen and reheated products

- Shear resistance – Withstands processing without breaking down

Common food products containing E1450

You’ll find E1450 in many everyday products:

- Bakery items – Cakes, pastries, pie fillings

- Dairy products – Flavoured milk drinks, yoghurts, cream-based desserts

- Sauces and dressings – Mayonnaise, salad dressings, gravies

- Processed foods – Ready-meals, soups, frozen dishes

- Confectionery – Custards, puddings, fillings

| Application Area | Role of E1450 |

|---|---|

| Bakery | Improves crumb softness & shelf life |

| Dairy | Enhances creaminess & prevents separation |

| Sauces & Dressings | Thickens without lumping |

| Processed Foods | Maintains texture after reheating |

| Frozen Foods | Prevents ice crystal formation |

Benefits in food manufacturing

Food producers choose E1450 for several reasons:

- Consistent quality across production batches

- Reduced processing waste through stable performance

- Enhanced product appeal with improved texture and appearance

- Extended shelf-life and better storage stability

- Versatile use across both hot and cold food systems

Global Market Overview of E1450

The E1450 modified starch market has seen steady growth over the past decade, driven by its versatility and increasing demand from the food manufacturing sector. Globally, the market value for distarch phosphate is estimated in the hundreds of millions of pounds, with consistent year‑on‑year growth as more manufacturers use it across a wider range of products.

Key geographic markets include:

- North America – Strong demand from the bakery and convenience food sectors, with established supply chains.

- Europe – A mature market with strict food safety regulations; the UK, Germany, and France are among the largest consumers.

- Asia‑Pacific – The fastest‑growing region due to expanding processed food industries in China, India, and Southeast Asia.

Emerging markets and growth hotspots are being seen in Latin America, the Middle East, and Africa, where rising urban populations are increasing the need for ready‑to‑eat and packaged food products.

Market segmentation by application typically falls into:

- Bakery and confectionery – for texture and volume improvement.

- Dairy and desserts – for creaminess and stability in heat‑treated products.

- Processed and packaged foods – for thickening and shelf‑life extension in soups, sauces, and ready meals.

- Gluten‑free and plant‑based products – as a functional replacement for certain texture‑giving ingredients.

Overall, the E1450 food additive market benefits from its adaptability across multiple applications and regions, making it a key player in the global food additives industry.

Drivers Fueling Demand for E1450

E1450, also known as distarch phosphate, is seeing increasing demand in the UK food sector thanks to several industry and consumer trends.

Increasing Processed Food Consumption

Busy lifestyles are driving higher consumption of processed, packaged and frozen foods. E1450 helps manufacturers maintain consistent texture and stability in these products, even after long storage or heating.

Preference for Better Texture

UK consumers now expect ready meals, sauces, dairy desserts and bakery goods to have the same mouthfeel and quality as freshly made options. E1450 modified starch improves creaminess, thickness and stability, meeting those expectations.

Regulatory Approval and Safety

E1450 is approved for use by the UK Food Standards Agency, EFSA and other major global regulators, giving manufacturers and retailers confidence in its safety. This means it can be freely used in line with labelling rules.

Advances in Food Processing

Modern processing methods, including high-temperature cooking and freezing, can cause texture issues in foods. E1450 withstands these processes far better than many native starches, reducing waste and improving quality.

Demand for Convenience and Ready-to-Eat Foods

With UK households buying more microwaveable meals, soups, gravies and plant-based dishes, there is growing need for additives that keep these products stable, appetising and quick to prepare. E1450 fits this demand by holding shape and texture without affecting taste.

Key Challenges and Regulatory Considerations

Regulatory landscape for E1450

E1450 (distarch phosphate) is widely approved for food use by global authorities, including the European Food Safety Authority (EFSA), the US Food and Drug Administration (FDA), and Codex Alimentarius. In the UK, it remains permitted under retained EU food additive regulations, provided it meets purity criteria and is used within set limits for specific food categories. Manufacturers need to ensure full compliance with labelling rules, often listing it as “E1450 modified starch” on packaging.

Health concerns and consumer perception

While E1450 is generally recognised as safe, some consumers in the UK remain wary of “E-numbers” due to misconceptions about processed additives. This has led to stronger demand in certain market segments for clean-label or “no additives” products, especially in premium bakery and plant-based ranges. Addressing these concerns often comes down to transparent ingredient communication and highlighting the plant-derived origin of modified starches.

Supply chain and raw material constraints

E1450 production depends on starch sources such as corn, potato, or tapioca. Global supply can be affected by poor harvests, crop price volatility, and logistics disruptions. UK manufacturers importing E1450 must also navigate exchange rate shifts and post-Brexit trade procedures, which can add cost and lead times.

Alternatives and competitive additives

In the food stabilisers and thickeners market, E1450 competes with other modified starches (e.g., E1414, E1442), natural gums (xanthan, guar), and pectin. Alternatives are often chosen when a cleaner label is needed or specific functional properties, such as freeze-thaw stability or organic certification, are required. However, E1450 remains a cost-effective and versatile option for many processed food applications in bakery, dairy, sauces, and ready meals.

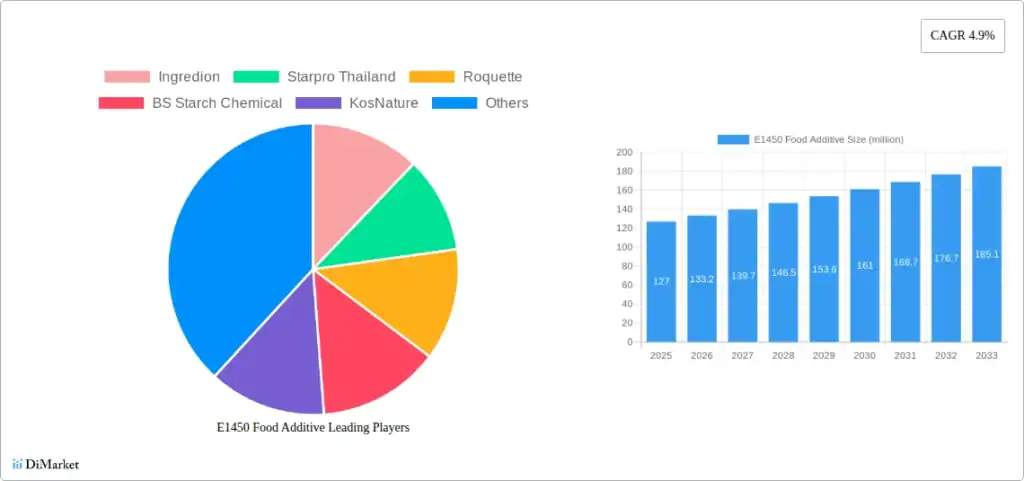

Competitive landscape and major players in the E1450 food additive market

The E1450 modified starch market is well established, with activity from both global manufacturers and smaller regional suppliers. In the UK and wider Europe, supply typically comes from a mix of multinational food ingredient companies and local producers with strong distribution networks.

Leading global suppliers include well-known food solutions brands based in Europe, North America, and Asia-Pacific, many of which offer E1450 alongside other modified starches for bakery, dairy, confectionery, and ready-meal applications. UK food producers often source from large international groups due to consistent quality, global regulatory compliance, and reliable supply chains.

Regional players—especially those in Eastern Europe and Asia—compete on cost and flexibility, often offering customised blends or tailored applications for specific food products. This appeals to smaller UK food manufacturers looking for niche solutions or price advantages.

Recent innovations in the E1450 space focus on:

- Cleaner processing methods

- Reduced environmental impact in production

- Improved functionality in cold or frozen applications

- Enhanced performance for plant-based and gluten-free products

Partnerships and collaborations are common, with UK importers and distributors teaming up with overseas factories to secure a consistent supply and meet local demand. Multinationals are also working closely with food manufacturers to co-develop products where E1450 plays a key role in texture and stability.

This competitive spread gives UK buyers access to a broad range of supply options—from high-volume global producers to more agile, speciality suppliers—allowing flexibility in meeting cost, quality, and innovation needs.

Market Trends and Innovations in the E1450 Food Additive Market

The E1450 food additive market is evolving quickly as food manufacturers adapt to shifting consumer trends in the UK and beyond. While E1450 (distarch phosphate) is a modified starch, there’s growing interest in clean-label and natural additive alternatives. However, its functional benefits – like stability, thickening, and texture control – keep it relevant, especially in products where performance matters more than label simplicity.

Clean Label vs Modified Starches

UK buyers are increasingly conscious of labels, favouring products with fewer additives. To address this:

- Brands are improving sourcing transparency for E1450 modified starch.

- Some are promoting plant-derived, allergen-free qualities for reassurance.

- E1450 is often chosen over other synthetic stabilisers because of its safety record and regulatory approvals.

Use in New Food Segments

E1450 is finding its way into plant-based and gluten-free ranges, supporting texture and shelf-life without affecting taste. Popular uses include:

- Non-dairy milks and yoghurts to prevent separation.

- Gluten-free bakery goods for a softer crumb and better moisture retention.

- Vegan ready meals for heat stability during re-heating.

Technological Innovations

Manufacturers are innovating in how modified starch E1450 is produced and applied, focusing on:

- Improved processing methods to enhance consistency.

- Better performance at lower usage levels, cutting costs and calories.

- Blends with natural starches to meet both functional and clean-label demands.

These innovations allow E1450 suppliers to target niche food categories, while also keeping pace with broader trends in the food stabilisers and thickeners market.

Future Outlook and Market Projections for E1450 Food Additive

Over the next 5–10 years, the E1450 food additive market is expected to see steady growth, driven by increasing demand for processed and convenience foods across the UK, Europe, and global markets. Modified starches like E1450 are playing a bigger role in food manufacturing due to their versatility in improving texture, shelf-life, and stability in a wide range of products.

Forecast trends and drivers:

Rising processed food consumption: Busy lifestyles in urban areas are pushing demand for ready-meals, bakery goods, and dairy desserts, where E1450 is a key ingredient.

Expanding plant-based and free-from ranges: Food producers are incorporating E1450 in gluten-free and vegan recipes to achieve desirable textures without animal-based thickeners.

Global and local supply chain advancements: Better manufacturing processes and sourcing efficiencies are reducing production costs and increasing availability.

Regulatory stability: Continued approval from bodies like EFSA and the FDA gives manufacturers confidence to invest in products containing E1450.

Potential growth barriers:

Increasing consumer demand for “clean label” formulations may slow uptake in brands targeting additive-conscious shoppers.

The presence of alternative natural starches may intensify competition, particularly within organic food ranges.

Opportunities for market entrants and investors:

Focusing on specialised functional applications like plant-based cheese, premium sauces, and frozen bakery where texture and stability are critical.

Investing in sustainable sourcing of raw starch to appeal to eco-conscious brands.

Developing cost-effective, high-performance blends of E1450 with other starches for niche industries.

Impact of sustainability trends:

Sustainability is increasingly influencing procurement decisions. This could spur demand for E1450 sourced from non-GMO, locally grown crops in the UK and Europe, lowering transport impacts and supporting local agriculture. Manufacturers aligning with low-carbon production and recyclable packaging will have a competitive edge when supplying to major food brands.

Why Choose Taichy Food for E1450 Solutions

At Taichy Food, we know the UK food industry needs E1450 modified starch that meets strict quality, safety, and performance requirements. Our approach is straightforward – consistent quality, tailored solutions, and dependable service.

Proven Expertise in Food Additives

We have years of experience in producing distarch phosphate (E1450) for a wide range of food sectors – from bakery and dairy to ready meals. Our production facilities follow strict quality control, ensuring consistency in texture, stability, and performance.

Quality and Compliance

We supply E1450 food additive that meets:

| Standard / Regulation | Compliance Status |

|---|---|

| British and EU food laws | Fully compliant |

| EFSA & FDA approvals | Approved usage |

| Halal & Vegan options | Available |

This means our E1450 is safe, reliable, and accepted for use across retail and manufacturing in the UK.

Customisation and Technical Support

We understand food manufacturers often need specific performance – whether it’s heat stability, freeze–thaw resistance or improved mouthfeel. Our team can:

- Adjust formulation for your specific product type

- Provide usage guidelines to optimise results

- Offer application testing for new recipes or product lines

Commitment to Innovation and Client Success

We invest in new starch modification technologies to deliver better results with cleaner labels. Working closely with UK brands, we help integrate E1450 into products that meet evolving consumer expectations – from plant-based meals to gluten-free baked goods.