Understanding Modified Starch Definition and Types

What is modified starch

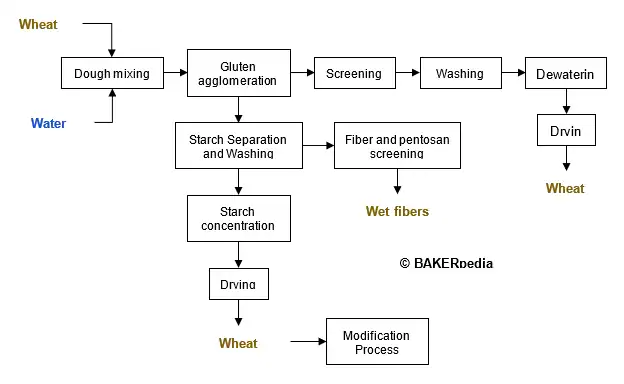

Modified starch is a starch that has been physically, chemically, or enzymatically altered to improve its functionality in food processing. While native starches from sources like corn, potato, rice, or tapioca have natural thickening and binding properties, they often fall short under certain production conditions like high heat, freezing, or extended storage. Modifying starch makes it more stable, adaptable, and effective for specific applications such as rice noodles, baked goods, and sauces.

Common types of starch modification

Starch modification can be carried out in different ways depending on the desired results:

- Physical modification – Heat treatment or mechanical processing changes starch properties without chemicals. This can improve water absorption and swelling capacity.

- Chemical modification – Safe, food-grade chemicals are used to introduce new functional groups, enhancing stability, viscosity, and resistance to breakdown.

- Enzymatic modification – Enzymes break down or rearrange starch molecules, creating more controlled textures and digestibility.

Why starch modification is necessary for rice and flour products

In rice and flour-based manufacturing, the performance of native starch alone often isn’t enough to achieve consistent quality. Modified starch plays a key role by:

- Improving product texture and mouthfeel, especially in gluten-free recipes

- Preventing syneresis (water loss) in refrigerated or frozen foods

- Enhancing dough handling and stability during mixing and baking

- Extending shelf life by slowing staling in baked goods

- Supporting uniform production results across batches

In short, modified starch ensures rice and flour products hold their shape, stay fresh longer, and meet consumer expectations for taste and appearance.

Functional Roles of Modified Starch in Rice Products

Modified starch plays a big part in making rice-based products taste better, feel better, and last longer. Here’s how it works:

Improving texture and mouthfeel

With plain rice starch, textures can be too sticky or too firm. Modified starch helps smooth things out, giving rice noodles more bite and bounce, rice cakes a soft and springy feel, and rice snacks the right level of crispness.

Enhancing water retention and moisture management

Moisture loss is a big challenge in rice products. Modified starch locks in water during cooking and storage, so noodles don’t dry out, and cakes stay soft longer without turning crumbly.

Increasing shelf life and stability

Modified starch slows staling by holding moisture and maintaining the product’s structure. Rice snacks stay crisp, and steamed rice cakes keep their tenderness even after a few days.

Role in gluten-free rice products

In gluten-free recipes, modified starch steps in to mimic the binding and elasticity you’d get from gluten in wheat. This keeps rice bread or noodles from breaking apart and helps capture that familiar chew consumers expect.

Examples of rice products that benefit

- Rice noodles: better elasticity, less breakage during cooking

- Rice cakes: softer texture, longer freshness

- Rice snacks: improved crunch, stable texture during storage

Functional Roles of Modified Starch in Flour Products

Modified starch plays a big role in getting the right texture, structure, and stability out of flour-based products. Whether you’re making bread, pastries, batters, or coatings, it helps improve the way dough and batter handle during mixing, baking, and storage.

Enhancing dough consistency and elasticity

In bread and pastry doughs, modified starch helps give a more stable, uniform texture. It supports gluten networks in wheat-based recipes or replaces them in gluten-free formulas, making the dough easier to work with and less prone to tearing. This leads to better shaping and more consistent results.

Improving baking characteristics

By improving gas retention during proofing and baking, modified starch helps boost volume and improve crumb structure. Baked goods come out softer, with a finer, even texture and an appealing bite—important for everything from sandwich bread to sweet rolls.

Controlling viscosity in batters and sauces

In batters and coatings, modified starch manages viscosity so coatings cling better during frying or baking. It also helps sauces made with flour-based roux have a smoother texture without breaking down under heat.

Increasing freeze-thaw stability

For frozen baked goods like pre-proofed bread or frozen pies, modified starch reduces water separation when thawed. This helps maintain product quality after freezing, keeping crusts from getting soggy and fillings from becoming watery.

Common flour product applications

- Breads – improved rise, softer crumb

- Pastries – better flakiness, moisture retention

- Batters and coatings – even coverage, crisp finish after cooking

- Frozen baked goods – stable texture after thawing

Technical Benefits of Using Taichy Modified Starch in Rice and Flour Products

When it comes to rice and flour products, Taichy modified starch is more than just a filler — it’s a problem solver that delivers consistent results every time. Here’s why many U.S. food manufacturers turn to it for everyday production needs.

Quality Assurance and Consistency in Production

Using Taichy modified starch keeps product texture, taste, and cooking performance the same across every batch. This reduces variability, lowers waste, and ensures customers always get the same eating experience — whether you’re making rice noodles, bread, or frozen dough.

Customizable for Different Formulations

Not all rice and flour products are the same. Taichy offers starch types that can be tailored for:

- Firm and smooth rice noodles

- Soft, moist cakes and breads

- Crispy snack coatings that stay crunchy

This flexibility helps match functional properties to exact product needs.

Cost Effectiveness and Processing Advantages

With Taichy starch, manufacturers can streamline processes and cut costs:

- Speeds up mixing and hydration

- Reduces ingredient breakdown during cooking or freezing

- Extends shelf life, cutting down returns and product loss

Example: In high-moisture rice cakes, Taichy starch helps hold water without making them soggy, so they stay fresh longer on the shelf.

Addressing Common Production Challenges

Taichy modified starch can tackle frequent quality problems such as:

- Cracking in rice noodles during drying

- Bread losing softness after a few days

- Frozen products breaking texture after thawing

Table – Common Issues and Taichy Starch Solutions

| Production Issue | Taichy Solution |

|---|---|

| Rice noodles break during handling | Enhances flexibility and reduces brittleness |

| Bread stales quickly | Provides anti-staling effect for lasting softness |

| Frozen batter separates after thawing | Improves freeze-thaw stability |

| Snack coating loses crunch | Helps maintain texture during storage |

For reference on how modified starch works in other food areas, you can check out how it’s applied in the meat products series and the dairy and beverage series — the benefits are just as impactful in rice and flour products.

How Modified Starch Affects Food Safety and Nutrition in Rice and Flour Products

Allergen Management and Gluten Free Benefits

One major reason food makers in the U.S. choose modified starch, especially in rice and flour products, is allergen control. Many Taichy modified starch options are naturally gluten free, making them a safe alternative for people with celiac disease or gluten sensitivity. In gluten free baking and rice-based snacks, they help replace wheat flour’s texture without introducing common allergens like wheat, soy, or dairy. This makes allergen labeling easier and supports compliance with FDA gluten free standards.

Calorie Content and Digestibility

Modified starch generally doesn’t add extra calories compared to native starch, but it can be tailored to change how the body digests it. Some versions can slow starch breakdown, which may help with better blood sugar management in certain product lines. For baby foods, sports nutrition products, or elderly diets, the right type of Taichy modified starch can support smoother digestion and improve mouthfeel without relying on added fats or sugars.

Regulatory Compliance and Clean Label Options

For U.S. manufacturing, meeting FDA labeling and food safety rules is a must. Taichy offers food-grade modified starches that comply with U.S. and international regulations. Certain variants are designed for “clean label” applications, which means they can be listed simply as “starch” or “modified starch” without chemical-sounding names. This helps brands meet market demand for simpler ingredient lists, especially in health-conscious or premium products.

Practical Tips for Choosing and Using Modified Starch in Rice and Flour Product Manufacturing

Choosing the right modified starch for rice and flour products comes down to knowing your end goal—whether that’s better texture, longer shelf life, or improved freeze-thaw stability. Here’s a quick guide to making smart choices and getting consistent results.

Criteria for Selecting the Right Modified Starch Type

- Match the function to your product: For rice noodles, go for starches that improve elasticity and reduce breakage. For baked goods, focus on those that enhance volume and crumb texture.

- Check processing conditions: High heat or shear during production may need a starch with strong resistance to breakdown.

- Consider dietary needs: Use gluten-free alternatives when targeting allergen-free products.

- Think about storage and shipping: Products traveling long distances may need anti-staling or moisture-control properties.

Dosage Recommendations and Typical Usage Levels

- Most applications use 2%–8% starch by weight of the flour or rice base.

- Start small, then adjust based on desired texture and moisture.

- For freeze–thaw stability in frozen goods, higher levels may be needed.

Integration into Production Lines and Formulation Tips

- Pre-blend modified starch with the dry ingredients for even distribution.

- If adding to a slurry or batter, disperse in cold water first to avoid clumping.

- Adjust water ratios—modified starch can hold more water than native starch.

- Run small-scale tests before full production to fine-tune settings.

Troubleshooting Common Issues

- Gummy or sticky texture: Reduce dosage or switch to a starch with lower viscosity.

- Dry or crumbly product: Increase starch level or pair with a moisture-retaining type.

- Inconsistent quality batch-to-batch: Review mixing times, water temperature, and supply consistency.

- Poor freeze–thaw performance: Choose a cross-linked or acetylated starch designed for low-temperature stability.